A brief introduction to the basic knowledge of PET bottle blowing

Taizhou Fupusi Machinery Co., Ltd. – Johntao@artinmachine.com

Introduction: When we pick up a common shampoo bottle, there will be a PET logo on the bottom of the bottle, which means that this product is a PET bottle. PET bottles are mainly used in the washing and care industry and are mainly large-capacity. In this article, we mainly introduce the PET bottle as a plastic container.

PET bottles are plastic containers made from PET plastic material through one-step or two-step processing. PET plastic has the characteristics of light weight, high transparency, impact resistance and not easy to break.

Manufacturing process

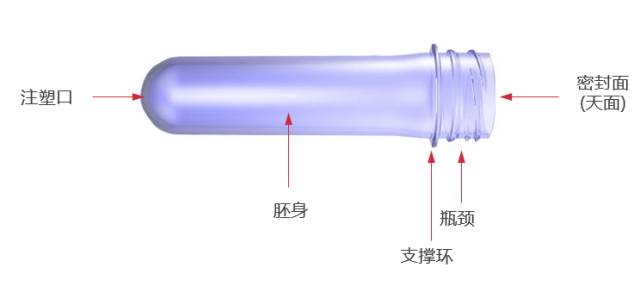

1. Understand the preform

The preform is an injection molded product. As an intermediate semi-finished product for subsequent biaxial stretch blow molding, the bottleneck of the preform has been finalized during the injection molding stage, and its size will not change during heating and stretching/blowing. The size, weight, and wall thickness of the preform are factors that we need to pay close attention to when blowing bottles.

A. Bottle embryo structure

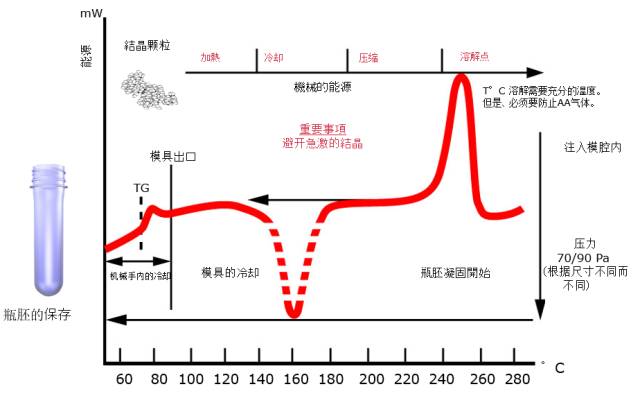

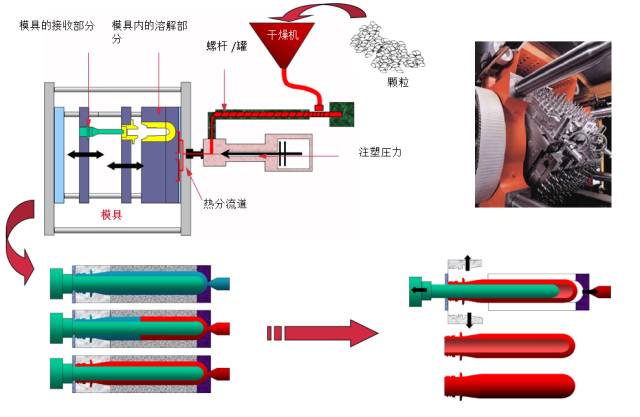

B. Bottle embryo molding

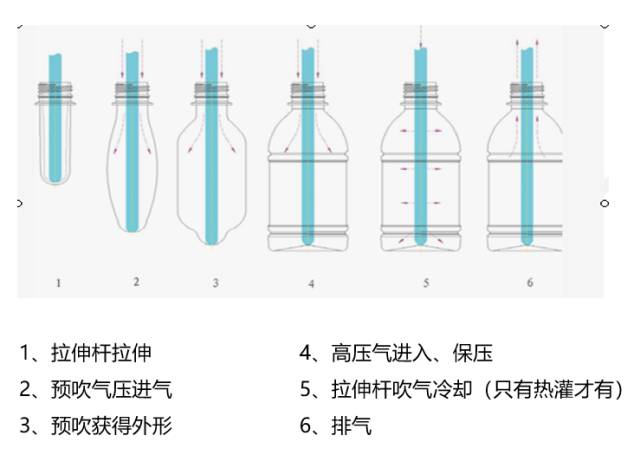

2. PET bottle molding

One-step method

The process of completing injection, stretching and blowing in one machine is called one-step method. The one-step method is to do stretching and blowing after the preform is cooled after injection molding. Its main advantages are power saving, high productivity, no manual work and reduced pollution.

Two-step method

The two-step method separates injection and stretching and blowing, and performs them on two machines at different times, also known as injection stretching and blowing process. The first step is to use an injection molding machine to inject the preform. The second step is to reheat the room temperature preform and stretch and blow it into a bottle. The advantage of the two-step method is to buy the preform for blow molding. It can reduce investment (talent and equipment). The volume of the preform is much smaller than that of the bottle, which is convenient for transportation and storage. The preform produced in the off-season can be blown into a bottle in the peak season.

3. PET bottle molding process

1. PET material:

PET, polyethylene terephthalate, referred to as polyester. The English name is Polyethylene Terephthalate, which is produced by the polymerization reaction (condensation) of two chemical raw materials: terephthalic acid PTA (terephthalic acid) and ethylene glycol EG (ethylicglycol).

2. Common knowledge about bottle mouth

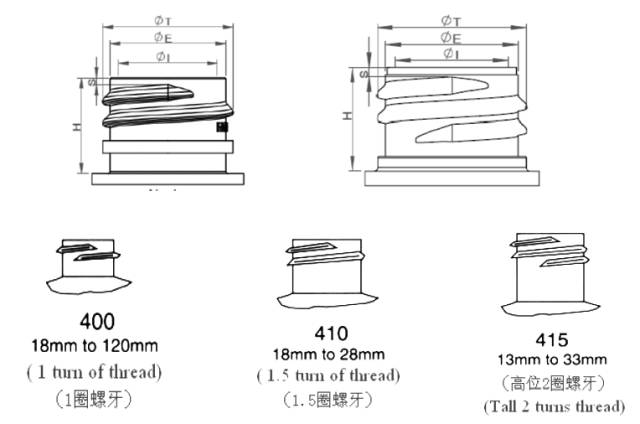

The bottle mouth has diameters of Ф18, Ф20, Ф22, Ф24, Ф28, Ф33 (corresponding to the T size of the bottle mouth), and the thread specifications can usually be divided into: 400, 410, 415 (corresponding to the number of thread turns). Generally speaking, 400 is 1 thread turn, 410 is 1.5 thread turns, and 415 is 2 high thread turns.

3. Bottle body

PP and PE bottles are mostly solid colors, PETG, PET, PVC are mostly transparent, or colored and transparent, with a sense of translucency, and solid colors are rarely used. PET bottles can also be sprayed. There is a convex point at the bottom of the blow-molded bottle. It is brighter under light. There is a bonding line at the bottom of the blow-injected bottle.

4. Matching

The main matching products for blow-bottles are inner plugs (commonly used for PP and PE materials), outer caps (commonly used for PP, ABS and acrylic, also electroplated, and electroplated aluminum, mostly used for spray toner), pump head cover (commonly used for essence and lotion), floating caps, flip caps (flip caps and floating caps are mostly used for large-circulation daily chemical lines), etc.

Application

PET bottles are widely used in the cosmetics industry,

mainly in the washing and care industry,

including shampoo, shower gel bottles, toner, makeup remover bottles, etc.

are all blown.

Purchasing considerations

1. PET is only one of the materials available for blow-bottles. There are also PE blow-bottles (softer, more solid colors, one-time forming), PP blow-bottles (harder, more solid colors, one-time forming), PETG blow-bottles (better transparency than PET, but not commonly used in China, high cost, high waste, one-time forming, non-recyclable materials), PVC blow-bottles (harder, not environmentally friendly, less transparent than PET, but brighter than PP and PE)

2. One-step equipment is expensive, two-step equipment is relatively cheap

3. PET bottle molds are cheaper.